Today, we’re tracing the evolutionary journey of handmade paper — an age-old craft that’s experiencing a quiet renaissance in our hyper-digital world. While often taken for granted, paper remains one of humanity’s most transformative inventions: a humble yet enduring material that has shaped civilizations, preserved stories, and continues to inspire creative expression.

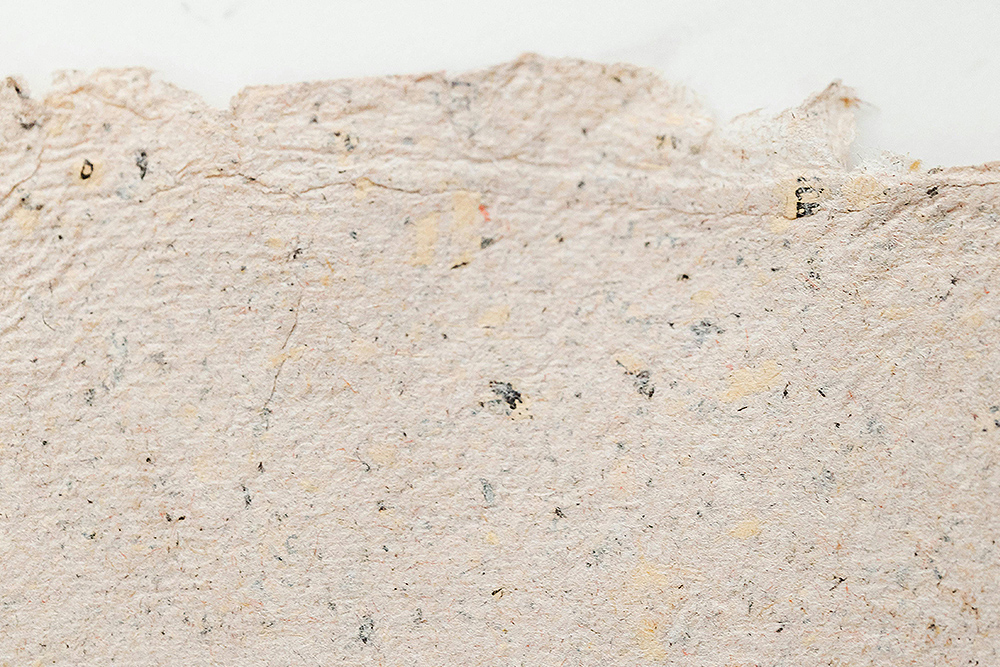

Though many know that paper’s origins lie in ancient China, the story of handmade paper becomes far richer, more textured, and quite literally more tactile when we explore how different cultures have embraced and reimagined it long before industrialization. Made sheet by sheet, using plant fibers such as mulberry, flax, cotton, or bark, handmade paper is formed by hand-lifting pulp onto a mould and deckle, then pressing, drying, and sometimes embellishing it with local techniques. The result is never just paper, but a material embedded with the marks of nature, tradition, and human touch.

From the silky strength of Japanese washi to the vibrant hues of Nepalese lokta, these paper traditions are a fusion of craft, culture, and ecology. And as designers, brands, and makers seek more sustainable, tactile, and authentic materials, handmade paper is finding its way back into the spotlight. So join us on a journey across continents and centuries, as we celebrate the global history and enduring relevance of handmade paper.

Before the Gutenberg printing press, before even parchment paper’s widespread use, there was zhi.

While some early forms of paper have existed since the 3rd century BCE, Cai Lun, a Chinese court official in the Han Dynasty in 105 CE, is the man traditionally regarded as the innovator behind zhi — early Chinese paper made from mulberry bark, hemp waste, and rags. Lun refined a process that involved pounding plant fibers into pulp, pressing them flat, and drying them into sheets. Lun’s innovation was more than technical — it democratized the written word and laid the groundwork for paper’s global spread. As by the 8th century, Chinese papermakers brought their knowledge to the West along the Silk Road. The famous Battle of Talas in 751 CE led to captured Chinese papermakers transferring the art to Samarkand (the oldest city in Central Asia), and from there, it moved into the Islamic world and further on into Europe.

Perhaps no country has elevated paper to such an artistic and cultural level as Japan.

Washi, which means “Japanese paper,” is made using traditional techniques that date back over 1,300 years. Unlike wood pulp-based Western paper, washi is made from the inner bark of plants native to Japan, like kōzo (mulberry), gampi, and mitsumata. The process of making Washi is meticulous and almost meditative, and involves hand-harvesting the fibers, boiling them, removing impurities, and forming sheets using the nagashizuki method (read a detailed explanation here), where the fibers are suspended in water and skillfully scooped onto bamboo screens. The result is a lightweight yet incredibly strong paper, known for its warm translucency, resilience, and expressive texture. Washi has long been used for everything from shoji screens and calligraphy to modern printmaking and packaging. Its status as a UNESCO Intangible Cultural Heritage of Humanity underlines its significance, not just as a craft, but as a living cultural artifact.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationThe long heritage of lokta in Nepal and the modern fusion of craftsmanship and innovation in India

High in the Himalayas, Nepalese artisans have been making paper from lokta, a fibrous shrub that grows in the foothills, for over a thousand years. Resistant to tearing, moisture, and insects, lokta paper was historically used for religious texts, government documents, and legal manuscripts. Its durability has kept ancient records intact for centuries. Harvested sustainably, as lokta regenerates quickly, the bark is boiled, pulped, and sun-dried on wooden frames in rural villages. The finished product, which is earthy, fibrous, and richly tactile, has seen a resurgence in recent years in packaging, stationery, and ethical branding design, thanks to its eco-credentials and raw beauty.

India’s paper history is more complex and multifaceted. While paper-making techniques didn’t arrive in the Indian subcontinent till around the 13th century via Islamic routes, a rich tradition of hand-crafted paper developed quickly. Made from jute, cotton, or recycled fabric, Indian papers are often vibrantly dyed, screen printed, or embedded with floral inclusions. The town of Sanganer, near Jaipur, became a center for hand-block printing on handmade paper, while artisans across the country still continue to innovate, merging traditional craftsmanship with modern applications in packaging, luxury branding, and sustainable design to this day.

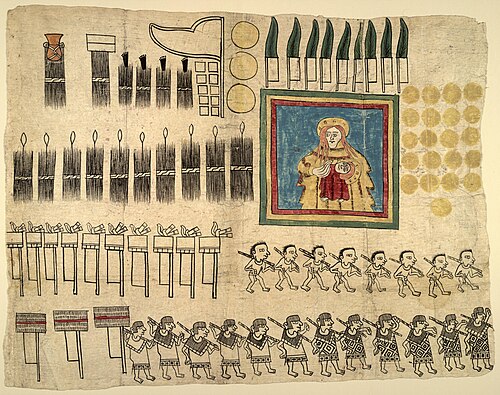

The bark books of the Mayan culture

Before the introduction of European paper during colonization, Mesoamerican civilizations such as the Maya and Aztecs used amatl or amate, a type of bark paper made from the inner bark of fig trees. The bark was soaked, pounded, and laid into sheets, then coated with lime to create a writable surface. This paper was used for religious texts, codices, and ritual documents, often vibrantly illustrated and folded like accordions. Though much of this heritage was destroyed during colonial conquests, a few surviving codices are invaluable records of pre-Columbian thought, art, and astronomy — and a testament to an ancient paper tradition far from the Eurasian continent.

Paper arrived in Europe around the 11th century, with Italy becoming a paper-making hub

Paper may have originated in Asia, but it was in Europe — particularly medieval Italy — where the craft evolved into a thriving industry that would shape the continent’s intellectual and artistic future. By the 13th century, towns like Amalfi, Fabriano, and Treviso had become paper-making powerhouses, known for refining and innovating traditional techniques. One of the most important breakthroughs was the introduction of water-powered hammers, which mechanized the labor-intensive pulping process, allowing for more consistent fiber preparation and increased output without sacrificing quality.

Another key innovation was gelatin sizing, a process in which sheets of paper were dipped in a gelatin solution made from animal hides. This made the paper more resistant to ink bleed and moisture, making it ideal for writing with quill pens and for intricate illumination. The result was a paper that combined durability with a smooth, absorbent surface — perfect for scribes, artists, and later, early printers like Gutenberg.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationUnlike Asian papers made from long plant fibers like mulberry, European handmade paper was typically crafted from cotton and linen rags, which were soaked, beaten into pulp, and formed into sheets using a mould and deckle. This rag-based paper had a softly textured finish and exceptional longevity, making it the medium of choice for everything from illuminated manuscripts and maps to scientific treatises and printed books.

The craftsmanship honed in early European mills laid the foundation for centuries of paper artistry. Today, their legacy is carried on by specialty papermakers who continue to produce fine, archival-quality papers for letterpress printing, lithography, and bookbinding. These traditional rag papers remain favored by artists, printmakers, and luxury brands for their unmistakable character, tactile richness, and deep connection to history.

For professionals in the design, packaging, and branding industry, handmade papers still offer something mass-produced materials simply can’t: texture, story, and authenticity

Each sheet carries the mark of its maker, the scent of its region, and the soul of a centuries-old tradition. Whether it’s the feathered edge of handmade paper, the natural variations of the fibers on the surface, or the sustainable sourcing behind the product, handmade paper provides a tactile and emotional connection that modern customers value. As craftsmanship, sustainability, and storytelling have become major selling points, revisiting the world’s paper traditions isn’t just an act of nostalgia — it’s an inspiration for the future of thoughtful, meaningful design.