The world of design papers is full of incredible haptic sensations, colours, fine-touch details and immense imagination to develop both aesthetically pleasing and technically high-performing papers for all the paper lovers out there. Such is the case for Pulse, our premium range of textured papers, which brings instant vibrant haptic sensations to the fingertips, when you come into contact with it.

Discover the Pulse range

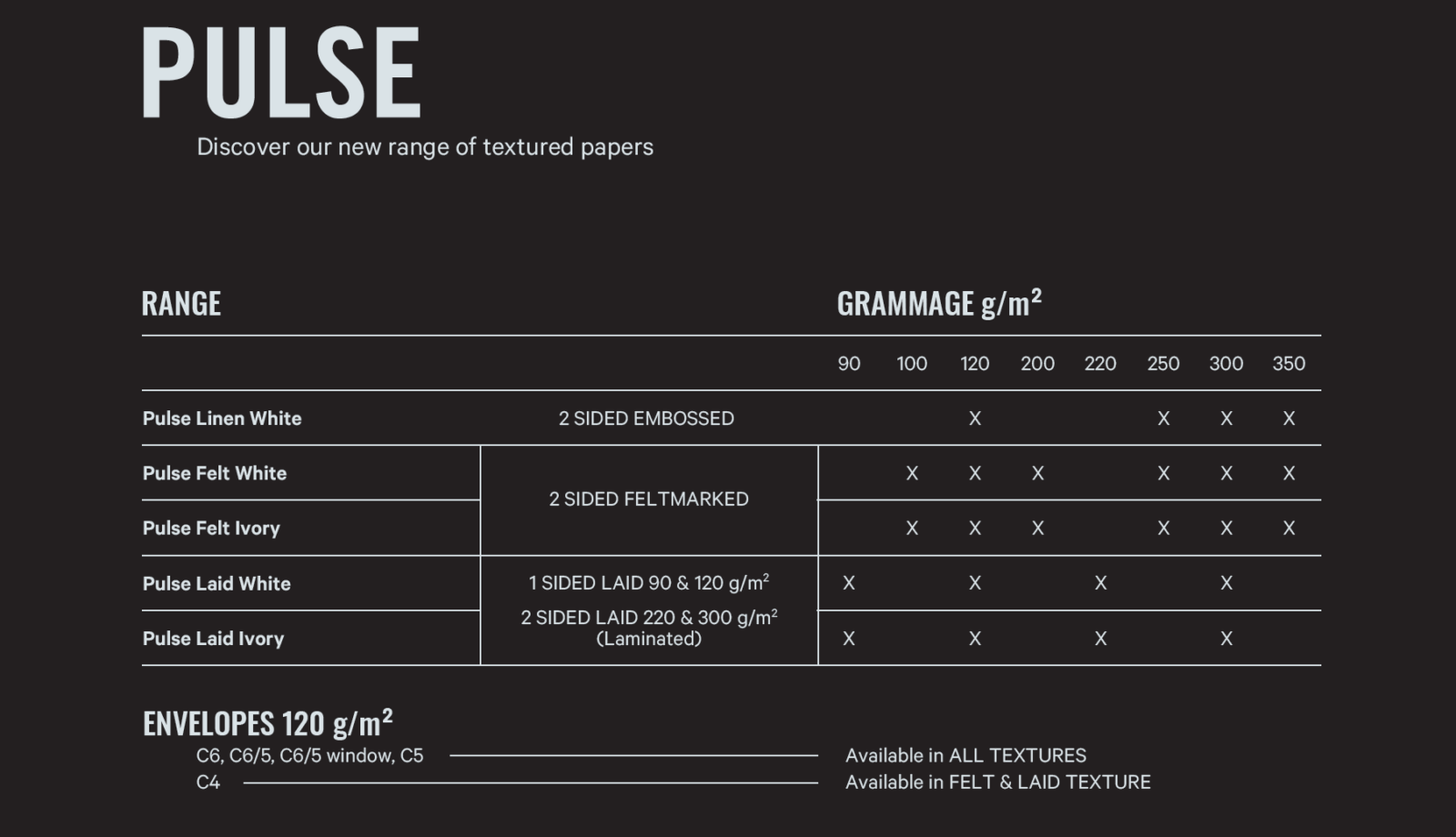

The range encompasses three different structures: Laid, Linen and Felt, and two shades: White and Ivory.

PULSE Laid is an elegant paper with a ribbed surface on one side. This paper has a traditional look and is ideal for prints that need to make an impression, such as invitations, high-quality brochures, or corporate documents.

Puls Felt is a felt-marked quality on both sides. The unique texture gives the paper a sophisticated look. Its excellent print quality makes it ideal for projects with higher graphic demands. Puls Felt is available in White (CIE 125) and Ivory.

PULSE Linen is a double-sided embossed paper that stands out for its finely textured texture that gives any print a luxurious and sophisticated look.

Pulse is the successor from our previous Via range, and delivers the same high quality material and exquisite print results.

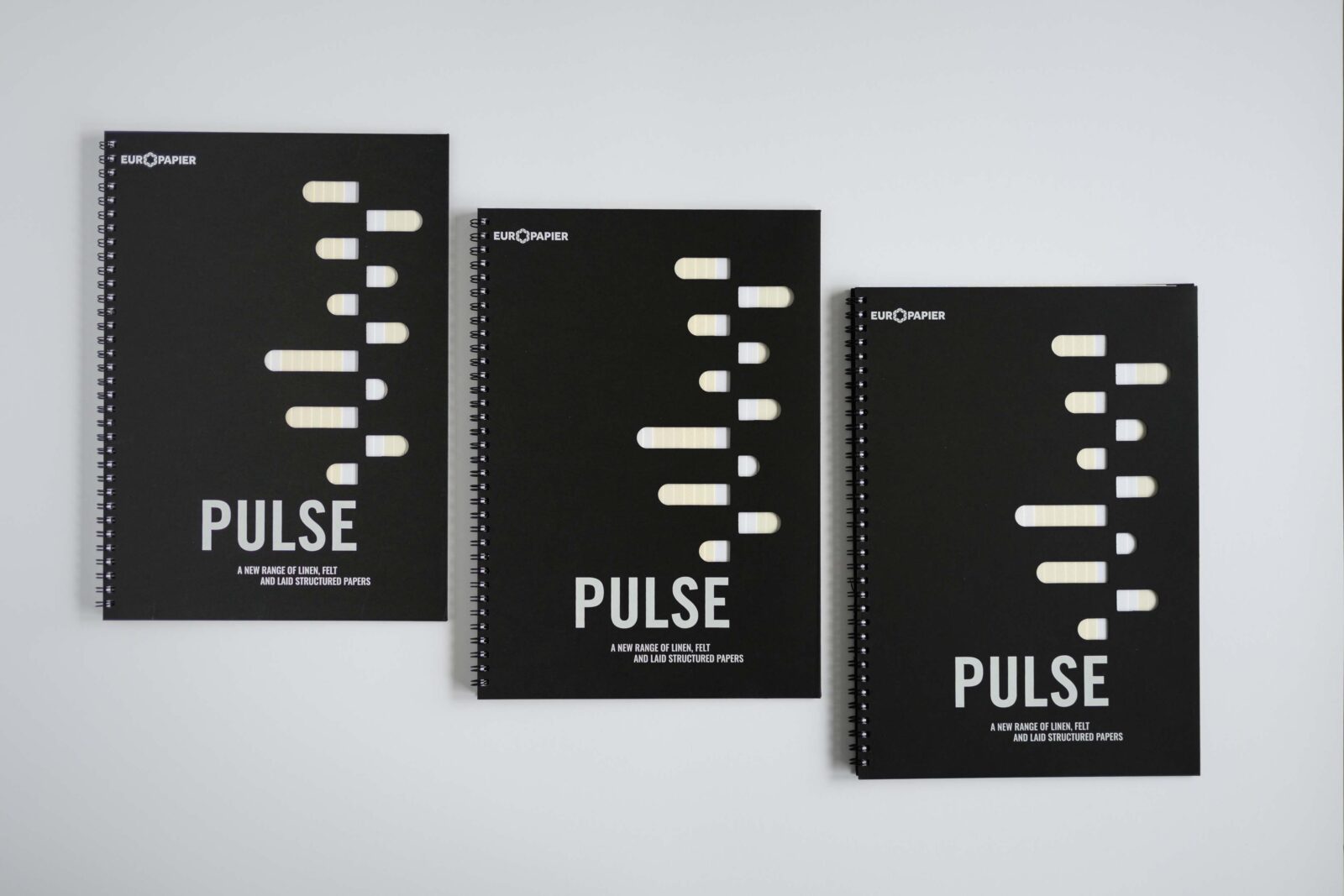

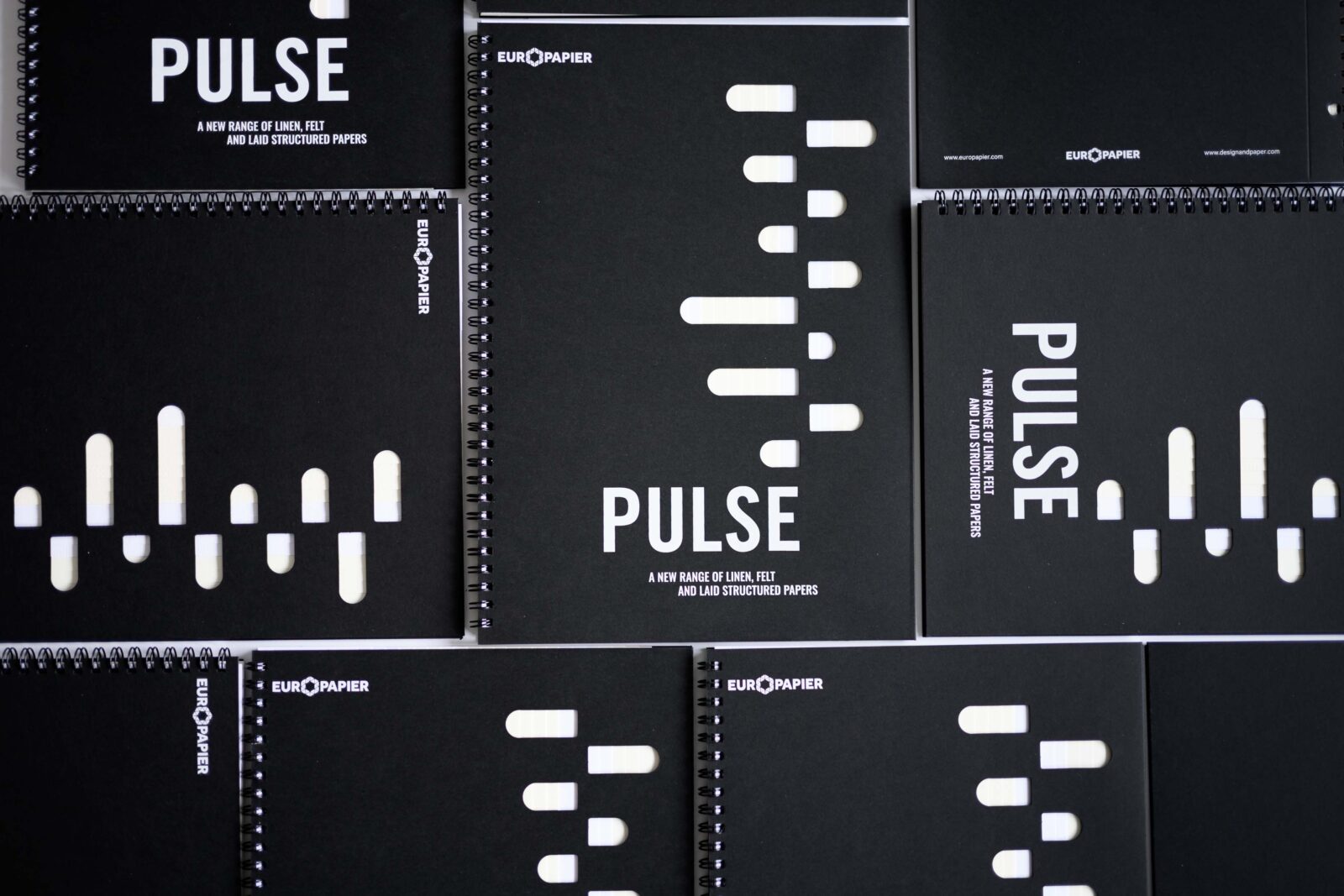

The Pulse Tool – Delivers beats at your fingertips

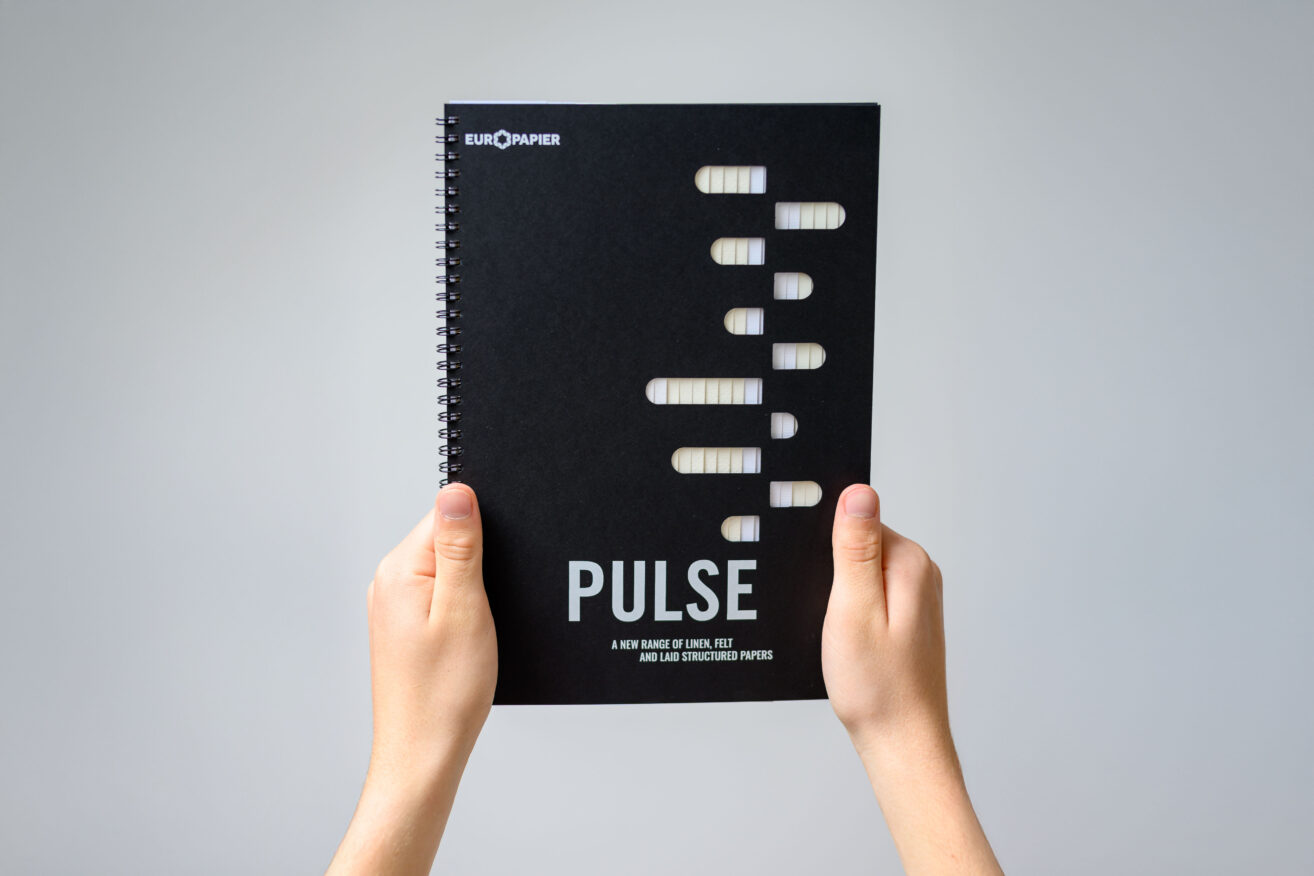

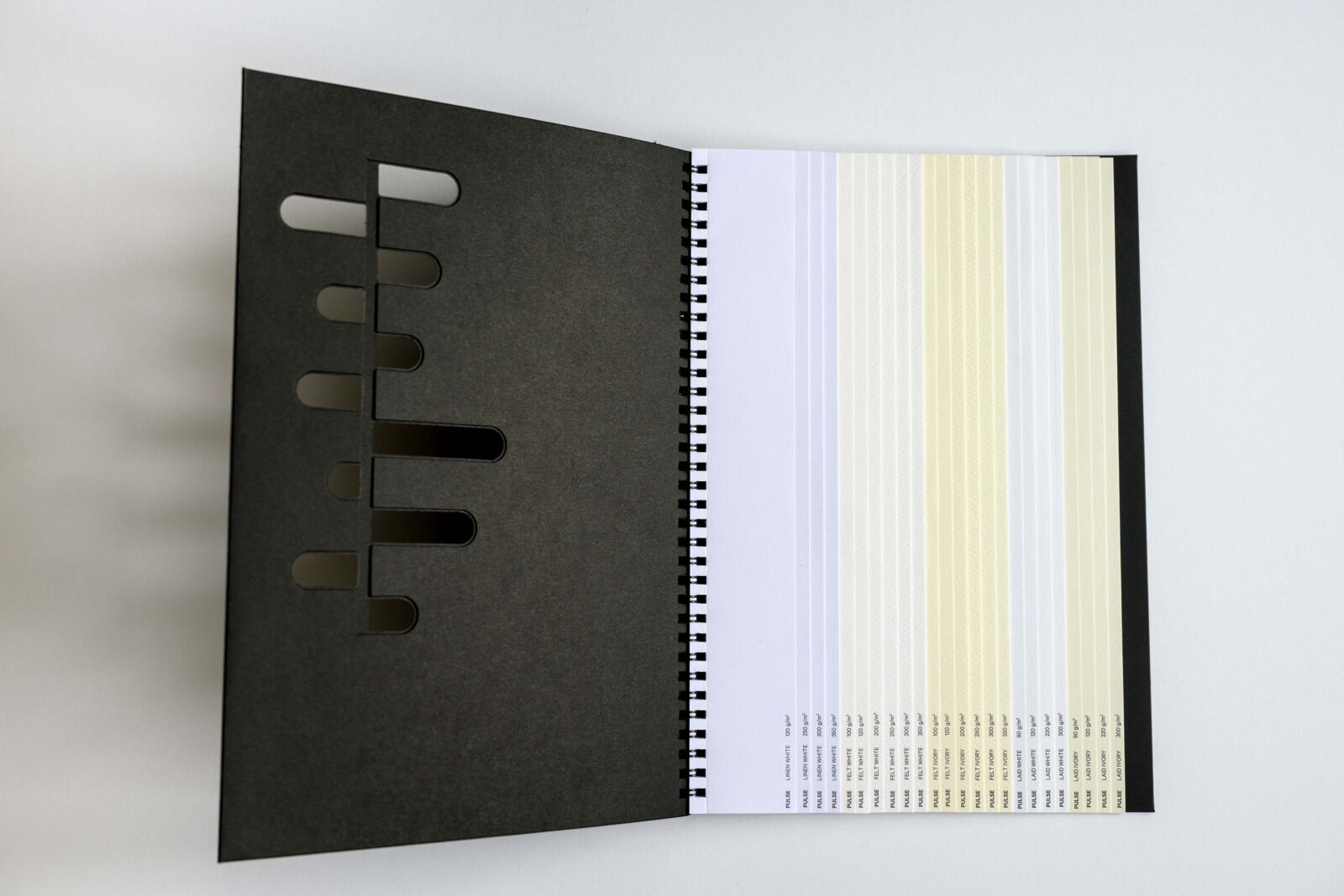

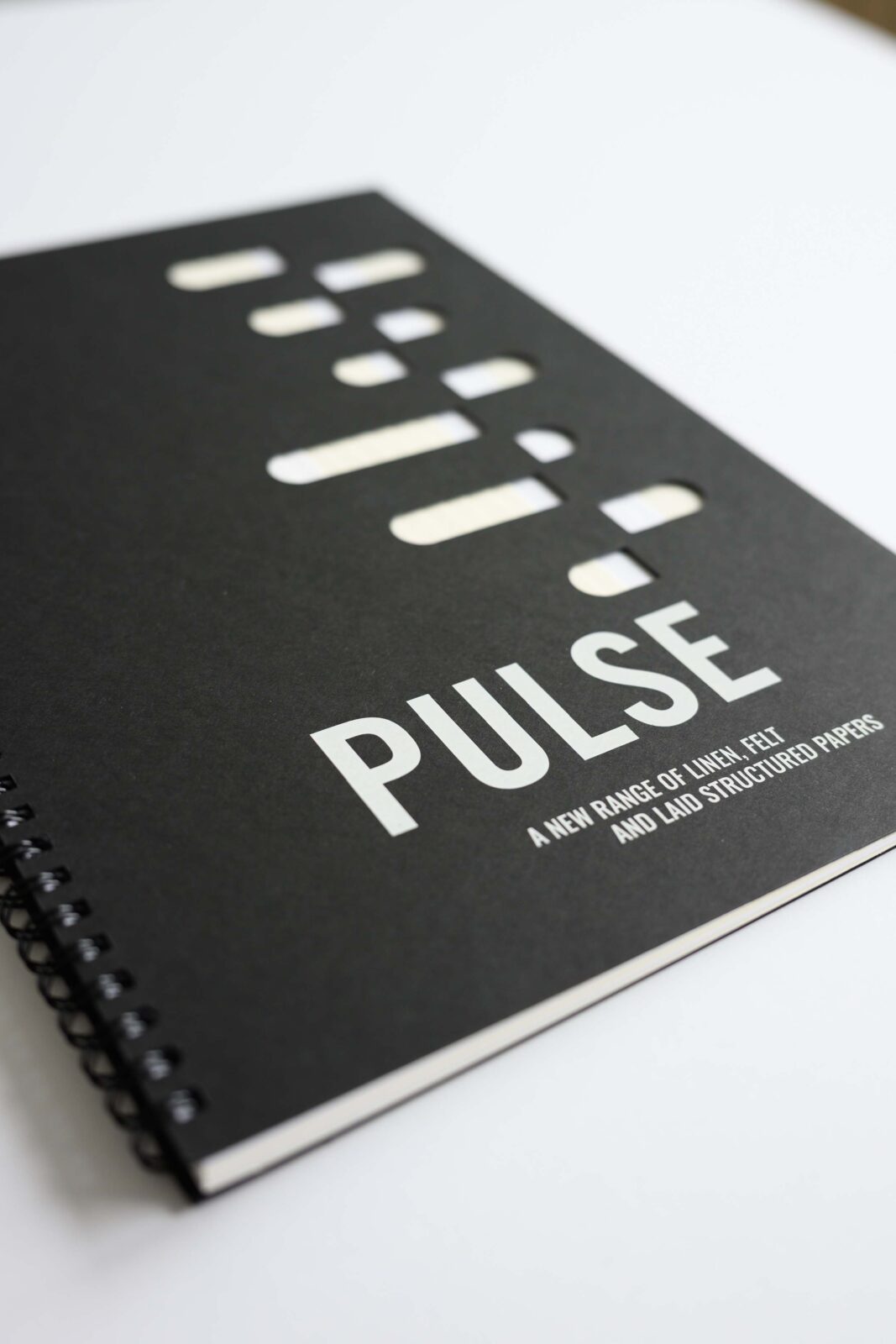

This year, we have also launched a printed tool, worthy of showing off these incredibly haptic design papers. The idea was that the paper takes the center stage, therefore the tool has a minimalistic design.

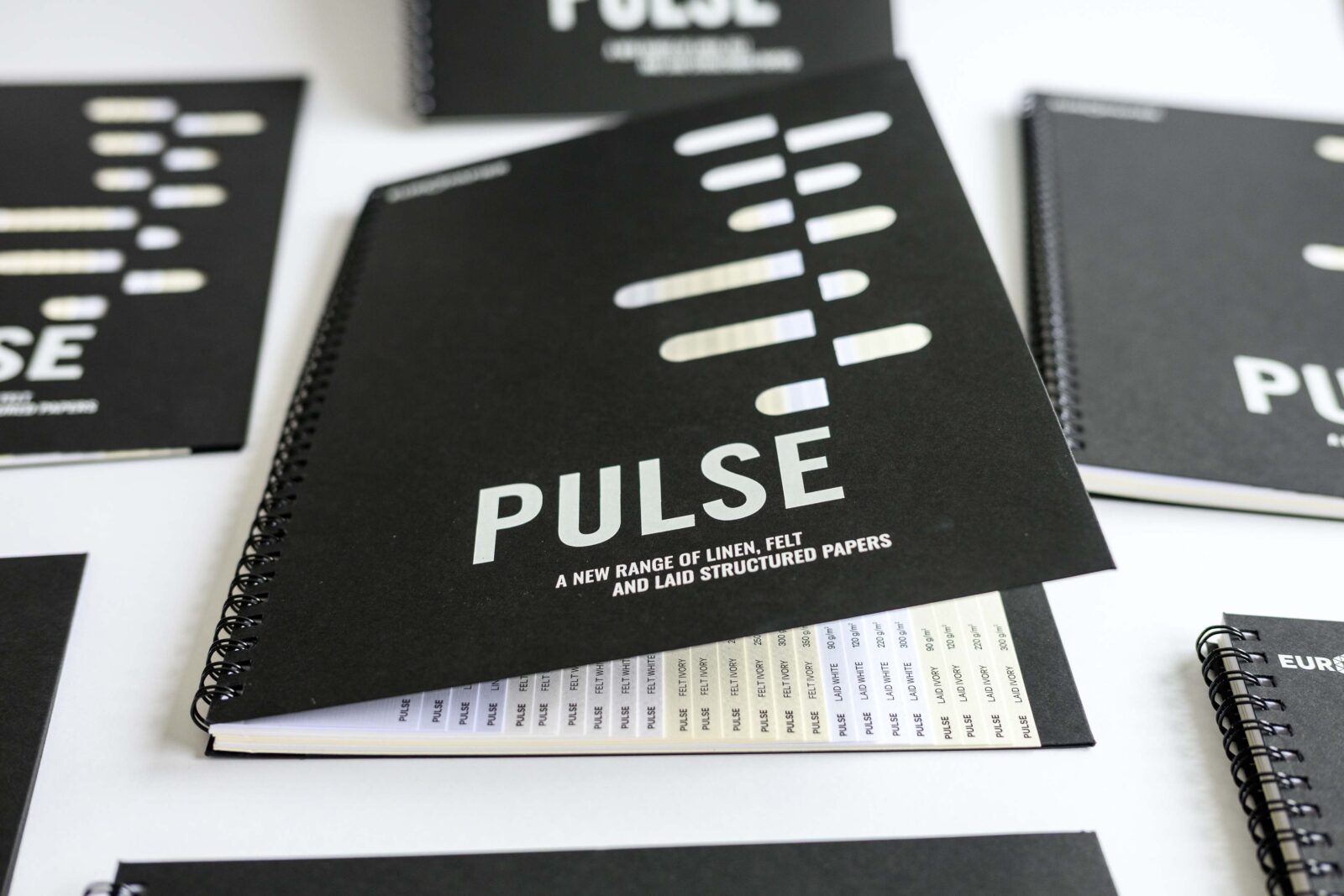

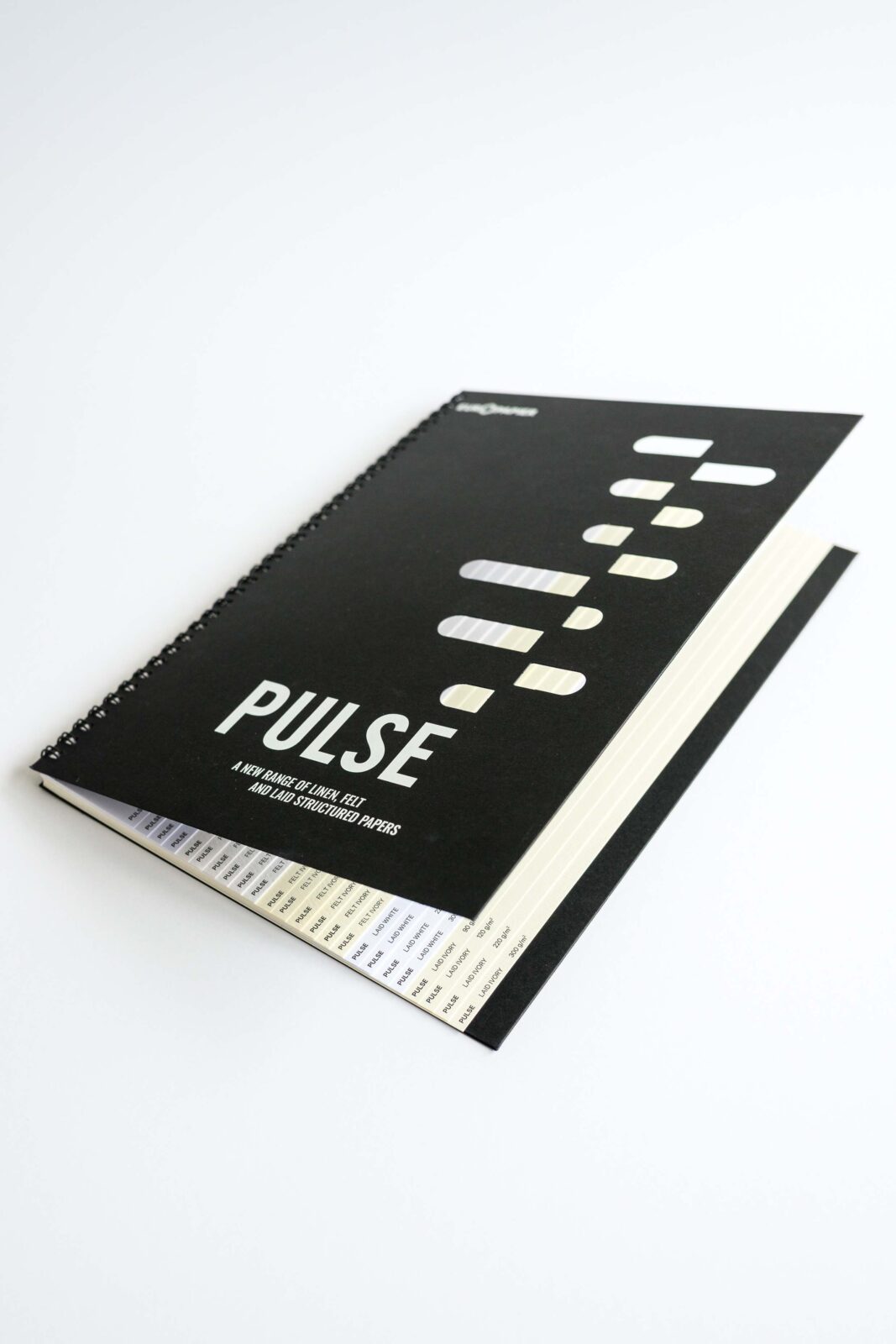

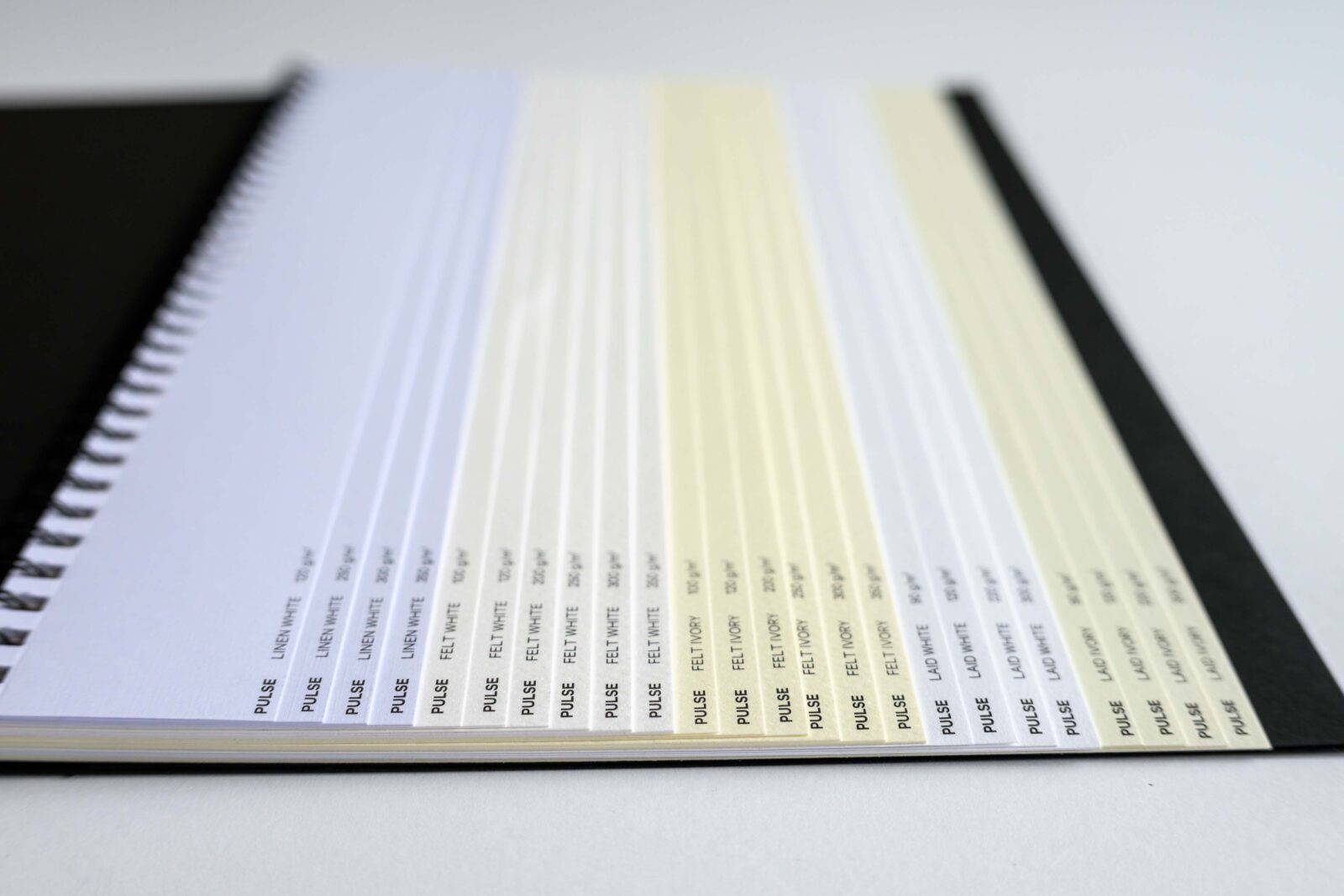

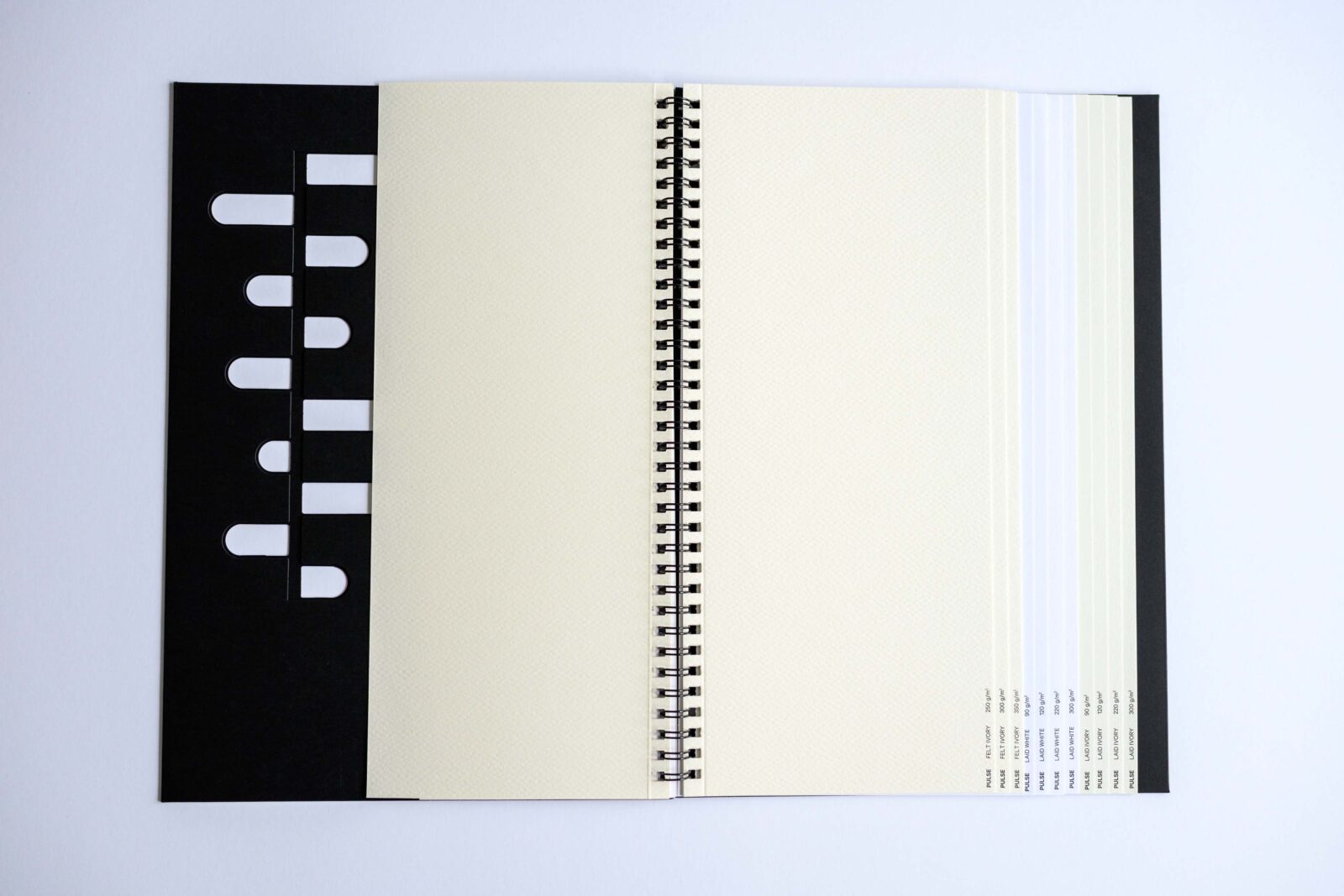

The different embossings and shades can already be observed without even opening the cover. We have included cut-outs in the cover, which are meant to symbolize beats. These cut-outs then transport the sensorial touch directly to your fingertips, already through the cover. Upon turning the cover, the whole range unfolds before you: each embossing, shade and weight is visible at once, giving you the possibility to glide your fingers over the paper waterfall like over piano keys.

Should one page appeal to you, or you want to look closely at each of them, you can turn the pages slowly and discover the paper in a bigger surface, from the smaller weights on the left side, to the heavier ones on the right side.

After flipping through the pages, you come to the last one, which contains the assortment overview of the range. The Pulse range starts off with 90 g/m2 and extends up to 350 g/m2.

Of course, worth mentioning are also the envelopes available for Pulse, which can beautifully complement your corporate communication, event invitations or mailings.

Printability & Runnability

Every method of printing, embossing, punching, creasing, die cutting, laminating and UV varnishing is possible.

Finishing

Prescoring is recommended for board weights and folding against the grain direction.

Environmental Profile

FSC® Certified; Biodegradable and recyclable; Acid Free; ISO 9706; Elemental Chlorine Free – ECF;

EN71 Toy Safety Standard; 94/62 EC – Heavy Metal Compliant.

Printing & Finishing recommendations for the Pulse range

Every method of printing, embossing, punching, creasing, die cutting, laminating and UV varnishing is possible.

Pulse Felt: Good quality semi-fresh inks. For heavier graphic elements and higher densities, oxidizing inks are suggested. The drying process can be slightly accelerated by adding extra desiccant. Otherwise print with UV inks.

Pulse Laid: To ensure good drying, use good quality inks, preferably new and undiluted.

Pulse Linen: Good quality semi-fresh inks. The drying process can be slightly accelerated by adding extra desiccant.

For a good graphic impression, use compressible multi-purpose blankets.

For the offset printing process a screen value of 150-162 lpi (Pulse Felt) 135-150 lpi (Pulse Laid) 150 lpi (Pulse Linen) is recommended. For dry offset printing this can be slightly higher for Pulse Laid and Linen, e.g. 200 lpi.

For heavier graphic elements and higher densities, sufficient powder should be applied.

Make small sheet pallets and allow at least 24 hours drying time after printing.

Prescoring is recommended for board weights and folding against the grain direction.

To avoid any curling issue, store the paper closed in it’s original wrap inside the printing area for at least 24-48 hours. After this conditioning time, the wrapping can be opened and the paper can be utilized.

Are you as facinated by Pulse as we are? Get in touch with your local Europapier representative today if you’d like to feel the papers yourself, or to receive your own Pulse Tool.

Images © Design&Paper